This post details the entire process: research, design and construction of our DIY boat lift canopy seagull or bird deterrent system. Feel free to skip to the end for pictures! Please leave comments with any questions you have and I'll try to answer them. More importantly please let me know if you used this design or found the post helpful and definitely link to pictures if you made one!!!

BACKGROUND

Let me paint a picture for you. It's a regular day at the lake and our

Gullsweep which was installed at the lake-end of the boat lift canopy was spinning and flapping quite nicely in the morning breeze. Blanketing the remainder of the canopy, just inches beyond the reach of the Gullsweep, were tens of seagulls squaking and defecating all over the place. That was the exact moment that I realized there had to be a better canopy bird deterrent system, and if not, we needed to create one!

The problem with the Gullsweep is simple geometry. The Gullsweep covers a circular area (6' diameter for the GS-1), but relatively small compared to the overall rectangular canopy which is 12'x27'. Originally, the Gullsweep was very effective, keeping the seagulls off of the entire canopy with the movement and noise of the plastic owl silhouetted vanes flapping over each arm rotation. It appears that the seagulls have become accustomed to the Gullsweep over time and now it's only effective over an area slightly larger than the swept area. Even if we we used the 8' versions AND had three of them equally spaced over the length of the canopy, there's still plenty of area for the birds to sit on the sides.

So, we started looking for other commercially available products that we could purchase to solve this problem. Surely there were other people with the same problem and an adequate product to solve it!

- We came across the Bird Spider, which is also circular and ultimately would have the same problem as the Gullsweep.

- We also found a few different variations using electrified strips of metal, but they were a) expensive and b) were intended more for edges or rails or peaks, all of which have a small area and are more linear compared to a large rectangular canopy c) would have required power out at the dock and d) would have affected the canopy and it's installation and removal.

- The Seagull Stopper was the first that we found of the "wire" concept and I really liked it for a number of reasons a) it was rectangular and could be modified to fit any canopy size b) doesn't rely on wind power (works without wind) and therefore doesn't have any moving parts c) not obnoxious looking d) effective based on two principles 1) that the wire acts as physical barrier or inhibitor to landing or taking off over a large area and 2) that if the bird chooses to land on the wire itself it unstable and therefore unsuitable. The latter is accomplished by various means but is primarily due to the flexible supports and line itself (and the addition of a spring in other products). Apart from the cost (which isn't that bad), the only downside for this product for us is the fact that the installation is not permanent and needs to be done every time the canopy is removed. We are on a northern lake so the canopy needs to be removed for winter. Installing the Seagull Stopper, which needs ladders, every season just isn't practical. If your canopy stays on year round, this may be the best solution for you. Most importantly for us, we had found a concept we liked, we just need to find a better support system.

- As soon as we knew what we were looking for we were able to find a bunch of variations on the "wire" or "line" concepts. Gulls Away, FLOE Bird Deterrent, The Dock Doctors and Seagull Eliminator are all very similar in function with minor differences in the mounting methods and the number of rows of wire/line. It's also possible that some of the canopy/lift companies use or rebrand one of the other OEM bird deterrent systems.

Gulls Away:

FLOE Bird Deterrent:

Seagull Eliminator:

The Dock Doctors:

We also found plenty of DIY examples including ribbons, streamers and CD's which seem to have a larger area of effect other than their footprint due to the obnoxious glinting and gleaming in the light and wind. Ultimately, we felt that these are equally obnoxious to humans.

One DIY solution that was up our alley was sent in by a reader and published on a

Boat U.S. page soliciting mariner ideas and methods for dealing with birds for their boats. This DIY bird wire system was used for a boat bimini and not a boat lift canopy, which in our case, is much more complicated.

DESIGN

The Seagull Eliminator people were kind enough to put an

installation manual online which includes a nice exploded view:

Additionally, Gulls Away put a nice snapshot of their mounting method on the

purchase page. Depending on how your canopy attaches to the frame, and if the cost isn't an issue, either of these two products may be right for you.

Our main problem with both of these two designs was that our canopy wraps up on the inside of the rectangular tube that both of these designs connect with (see below). You can also see the shadow of the Gullsweep post, and all of the seagull stains.

The other issue was that we didn't feel like paying HUNDREDS of dollars for a set of four or six bent poles welded to a pieces of angle and mounting hardware. At this point we had decided to design and fabricate our own bird wire posts and so started off with a list of design criteria.

- Should not significantly impact, in time or method, the canopy installation or removal.

- Should not contact the canopy in a way to increase stress or wear and degrade the life

- Installation or modifications to canopy frame should be simple and not compromise structural strength

- Should not be an eyesore (as much as possible)

- Minimize cost

With those criteria we started brainstorming. At first the simplest to fabricate seemed plate and tube welded or bolted together. Here are some of our back of the envelope sketches

We decided to go with the bent round tube designs after seeing so many variations thereof and with understanding round tube would have a very high strength to weight ratio. The problem now was seeing if we could bend the tube without kinking it. We bought a couple test sample pieces of varying diameter tube and solid rod. We found that we could bend the aluminum tube/rod around the horizontal cylinder of our vice and end up with a fairly neat, uniform 5 1/2" diameter bend. I was concerned about repeatability so we looked into tube benders but that was cost prohibitive (~$100) for the 1/2" OD tube.

My grandfather often used u-bolts in his contraptions so naturally it was agreed that u-bolts would be the best method to connect the tube to the frame, even though it involved drilling holes into the non-structural part of the frame. We decided to use flat spacers to suspend the tube off of the lift frame and allow the canopy securing flap to wrap under it. In retrospect, it probably would have been fine to have the tube interfere with the canopy securing flap similar to what happens at the much larger vertical rectangular support columns (below) as long as they landed in between the grommets and bungees.

We calculated that we needed 6' lengths of tube, but we could only find 3' and 4' lengths of tube in stock locally. We had to make a quick decision use 3/8" solid rod as an extension of the 1/2" tube, which worked well because the former fit perfectly (only slight clearance) inside the latter. We used a small bolt and lock nut to effectively pin/dowel them together. Assuming you can order 6' lengths of 1/2" tube, you can ignore that detail.

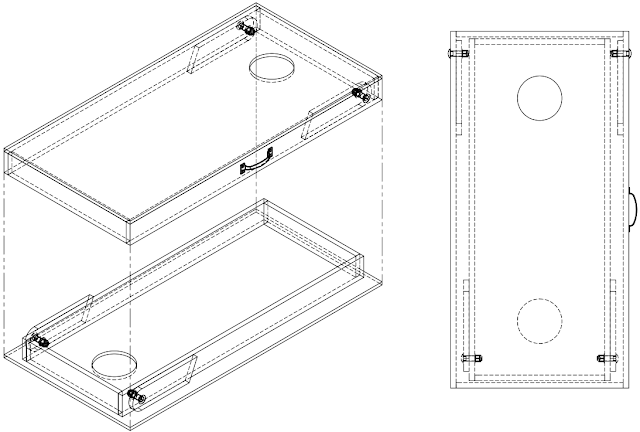

Here is a drawing of the post. This particular post goes on two of the four corners, catty-cornered from each other. The post for the other two corners just has the angles in the top view reversed.

Here are some renderings of the finalized design.

BILL OF MATERIALS (BOM)

Per Post:

- Preferred Option: 1/2" x 6' Aluminim Hollow Tube (length depends on height from frame mount, to bottom of skirt to top of canopy) - $Unknown

- Alternate Option 1: 1/2" x 6' Aluminum Solid Rod (heavier, more expensive) - $Unknown

- Alternate Option 2: 3/8" x 3' Aluminum Solid Rod - $5.36 ea. and 1/2" x 3' Aluminum Hollow Tube - $8.61 (if you can't get 6' lenghts)

- (Qty 2) 1/4" x 3/4" x 2" Stainless U-bolt with Plate - $1.89 ea. ($0.78 ea. for non-stainless)

- (Qty 4) 1/4" Stainless Locknut - $6.49 for 40

- 3/16" Stainless Eyebolt - $0.99 ea.

- 3/16" Stainless Locknut - $0.47 ea

- (Qty 2) 1/4" thick x 3/4" wide x 1 3/4" long Aluminum Spacer (made from 1/4" x 3/4" x 36" flat bar) - $20 for one bar which is enough for all spacers

- #10 x 1" Stainless Machine Screw (if using Alternate Option 2)

- #10 Stainless Locknut (if using Alternate Option 2) - $1.59 for 6

- #10 Stainless Flat Washer - $0.98 for 20

- 1/2" Plastic Cap (Qty 2 if using Preferred Option) - $0.99 for 4

Cost Per Post: $25.87

Wire System:

- 1/4" x 3" Steel Spring - $1.89 ea

- 50# Fishing Line (~100 yards per canopy) - $12.84

Wire System Cost: $14.73

Total Cost Per Lift: $118.21 (4-post) $159.95 (6-post)

TOOLS

- Drill or Drill Press (preferred)

- 9/32" Drill Bit (for u-bolt)

- 7/32" Drill Bit (for eyebolt and connecting bolt)

- 7/16 Open Ended Wrench or Ratcheting Wrench (preferred)

- Hacksaw or Reciprocating Saw (preferred)

- Punch or Automatic Punch (preferred)

- Flat metal file

- Safety Glasses, Gloves

CONSTRUCTION

This section will go step-by-step through the fabrication, assembly and installation of the bird wire system.

1. Post Fabrication

1a. Mark the 1/2" aluminum tube with a sharpy where you calculate the center of the bend to be.

1b. Using an appropriately sized and fixed cylindrical object as a makeshift bender, SLOWLY bend the 1/2" aluminum tube to make sure it doesn't kink. The bending process for one tube took probably around 2-3 minutes. Make sure to bend in small increments and continue to check how you are doing with your center mark. If you used 6' tube you should end up with a "U" shape with one side about twice as long as the other. If you had to use a 3' or 4' tube one side will only be slightly longer than the other. We bent the tube about 170 degrees, leaving a slight "V" to allow the tension of the line to eventually straighten the posts.

1c. If you use 1/2" hollow tube make sure to put a piece of 2 1/2" long 3/8 alumnum rod in the end that will mount to the canopy and stake it in place. We used a fine point punch to do this at the end of the tube at four spots around the diameter.

1d. This is where things get complicated. If you want the posts to be angled out towards the front or back of the canopy when installed (instead of at right angles) then you need to drill the mounting holes at about 30 degrees off angle from tube-to-tube. We ended up using a jig on the makeshift drill press to get some repeatability. Mark the tube 3/4" and 1 3/4" (note that the difference between these two numbers is 1" which is the distance between the centers of the U-bolt) from the end of the tube that mounts to the canopy. Make sure to drill the hole as close as possible to the center of the pipe and that the distance between the holes is as close to 1" as possible. Make sure to secure the pipe when drilling and that you don't let the bit wander. Use an punch to help center and start your bit on the curved surface. Drill these two holes using the 9/32 drill bit. If you have trouble fitting the U-bolts then you may need to go to 5/16, but that doesn't leave much material on the sides of the tube after drilling the holes.

1e. If you had to go with two-piece construction (

Alternate Option 2) for the posts (3/8" rod and 1/2" tube) then at this point you need to combine the two. Insert the 3/8" into the 1/2" tube just enough to get the desired overall height, and then drill them (location isn't important) together using the 7/32" drill bit and attach them together using the #10 screw and locknut.

1f. Mark, punch and drill a hole 3/4" from the end of the rod or tube (depending on one or two-piece construction) that is to have the line attached. Make sure to drill the hole such that the eyebolt will generally face towards the canopy center. This angle isn't super critical because the eyebolt will work +/- 45 degrees, more aesthetic than anything. Again we used a jig to drill the holes at the correct angle and ensure repeatability. Insert the eyebolt with the eye oriented vertically, facing towards where the canopy would be and tighten using a locknut on the opposite side.

1g. Using a file, slightly round the edge of the end of the tube that mounts to the canopy, in order to attach easily the cap. If you used Option 1, also do so at the other end that supports the string.

2. Spacer Fabrication

2a. Using 1/4" x 1 3/4" (min) flat aluminum bar, cut off pieces 3/4" long, corresponding to twice the number of posts you are using. Ideally a bansaw can be used, but a sawsall and hacksaw will suffice as well. File edges for safety and appearance.

Drill 9/32" holes 1" apart in the center of the plate

3. Post Installation

The cross member of our Harbor Master lift has a non-structural lip that we were able to drill through. I take no responsability for any damage you may do to your lift as a result of trying to replicate this on Harbor Master and especially any other type of lift.

3a. Mark, punch and drill two 9/32" holes 1" apart, starting ~4.5" from the end of the canopy frame. This was in far enough from the end of the canopy to still have the rod to attach to and not so far in that the angle of the post wouldn't allow the wire to be near the end of the canopy. If you have a canopy larger than 25' it is recommended that you have 6 posts, 2 in the middle of each long side. The positioning and drilling of these poles isn't critical, just make sure they are relatively even.

We value our lake being clean of debris, especially harmful objects such as glass and metal. This includes the aluminum shavings from drilling the frame. So, we used either pillow cases or over-sized ziplocks bags clothes-pinned to the frame to catch the aluminum shavings.

3b. Install the post using the U-bolts with plates and fabricated spacers where necessary to achieve separation from the cross member and making the inside post as vertical as possible.

4. Line Installation

4a. Have a plan for running the line from post to post. You should be able to do it with retracing only one of the lengths for the four post version and two lengths for the six post version.

4b. Start first by tying the spring to the fishing line using a good non-slip knot. We use a bowline knot. This will serve as a weight to keep the line from blowing in the wind too much and also allow you to fling it across the canopy to save time.

4c. Using ladders, start threading the spring through the eyebolts in the order you have planned. Leave the spool on the dock or boat in a position so that it continues to unravel freely as you progress.

4d. Tie a short jumper line from the other end of the spring to the last eyebolt as shown below. Then at the starting eyebolt near the spool, pull the line taught to the point where the posts start bending in and there is still PLENTY of flex in the line. Remember it should not be taught enough for a seagull or large bird to stand on. I found the the spring actually didn't flex, just the line. The below image shows the line ~4" above canopy as planned. You can also see how much of a seagull problem we USED to have.

FINISHED PRODUCT

Posts installed without line. You can see how the posts all angle outward somewhat.

Final installation with line. The posts are now mostly vertical, some angling in slightly. Note the seagull flying by... scared of the BIRD WIRE!

UPDATE: After two months we haven't seen any seagulls land on the canopies. Over the same time we have seen tons of seagulls land on our neighbor's canopy, which has no seagull deterrent. It WORKS! You can see in some of the pictures that the rods are a little bent. I think I tightened the fishing line a little too much. I might splice in a foot of line next year.